I had a HUGE reply typed up explaining everything.. and the computer froze up:mad:

In a nut shell, anti-dive in the front should be kept below 100% or else it can have a tendency to actually RISE when you hit the brakes. Now the calculator won't take weight transfer into consideration, so in reality it will probably take more like 130-150% anti dive for this to happen in real life.. but any time the suspension gets loaded it potentially want to rise... such as when climbing.

I shot for 70% and it acts normal... feels good... and climbs well.

Roll axis angle is WAY more important overall though as far as driving on the street goes... Basically as the body rolls in a turn, it will input addition steering feedback due to one of the links getting longer or shorter as the inside suspension extends and outside suspension compresses.

Negative = good

Positive = bad

You can affect it by 1) changing the angles of the LCAs as viewed from the top, 2) keeping the LCAs as flat as possible as viewed from the side, and 3) raising or lowering the track bar.

Put the track bar as high as possible(both frame and axle end... it goes off of the track bar's "average" height meaning halfway between both ends)... and if you angle your LCAs inwards this will basically allow them to "intersect" each other if you were to draw a line back to where they would meet if they were infinitely long. Making them flatter as viewed from the side helps too as it keeps that line from raising up in the air to the point that they intersect higher than the track bar.

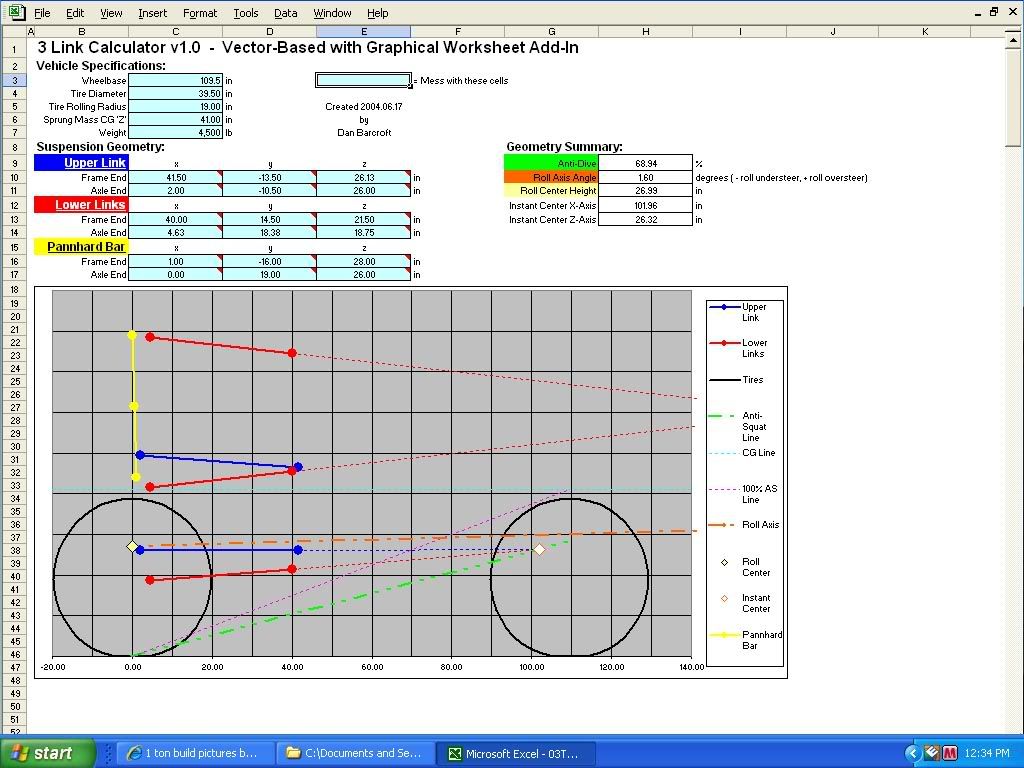

Here is my 3-link graph... works well... if you have any questions in particular shoot me a PM

edit:

Y-links are terrible because the Y-link center joint is almost NEVER mounted correctly and will be very likely to bend a heim or break entirely. They also have to pivot about that point... so the axle swings wildly left to right... it is worse the more vertical separation that you have at that upper point to the axle tube center line.

FWIW I ran Ballistic 2.63" joints on my lowers, and 3.0" joints for my single upper. I killed all (4) lower joints in about 1000 miles of street driving. So I bought (2) 1.25" heims and (2) Ballistic bushings... heims on axle end bushings on frame end.

Killed the bushings in about 300 miles of street driving.

Now I have (4) Ruff Stuff 1.25" heims and they are all holding up well with a few wheeling trips on them all... Now about 1200-1300 miles since the bushings were replaced... so about 1500 miles on the axle end heims and 1200-1300 on frame end heims.

No problems from the 3.0 Ballistic joints, but they are a ***** to package. Will be using all Ruff Stuff heims from now on. That was a $200 lesson learned.