|

|

|

|

#1 |

|

Mechanical Animal

- CORE Member -

- Moderator - Join Date: Feb 2008

Location: Beechmont

Posts: 1,883

|

Broken XJ door-hinge welds: cheap n easy fix!

Like many XJs (especially the two-doors) my driver's door has sagged badly for years. Last week, the damn thing finally fell off in the driveway. That's how I know it's time to fix something.

For those that don't know, the problem stems from AMC's lame-brained idea of welding the hinge to the sheet metal unibody (bad enough) and then neglecting to weld the rear edge (even worse.) As those welds start to crack, the hinge separates from the body, and the door sags. Eventually, the hinge can break all the way off, and you're done. I'm a pretty mediocre welder. I can stick plate to plate pretty well, and sheet to sheet pretty badly. But sticking the ~3/8" hinge back onto the cracked, rusty sheet metal just wasn't going to happen for me. I considered paying a friend to do it, but he was busy and I was broke. So I came up with this...

__________________

DIRTY DEEDS, DONE DIRT CHEAP

Whatever doesn't kill you makes you stranger |

|

|

|

|

|

#2 |

|

Mechanical Animal

- CORE Member -

- Moderator - Join Date: Feb 2008

Location: Beechmont

Posts: 1,883

|

First, I cut out the ruined sheet metal where the hinge broke off. That left about a 2-1/2x3" opening.

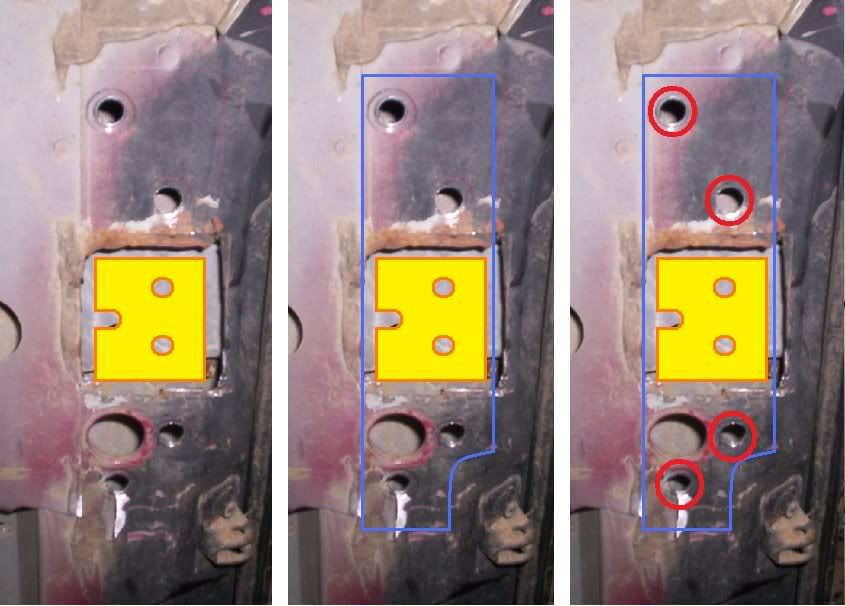

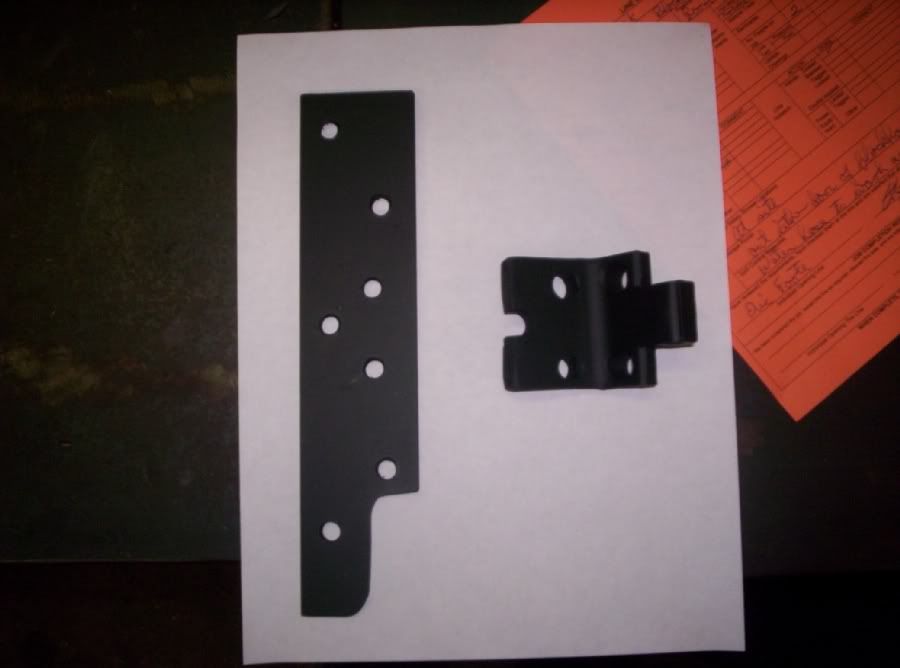

Then I could see that there's enough space behind that panel for a new, stronger mounting plate. So if I needed to mount the hinge like so (the yellow), I figured I'd need a plate shaped something like the blue outline. So I drilled (4) 3/8" mounting holes (red).  Then I cut my new mounting plate. I used about 8" of 2x1/4" flat stock. If you were careful and spaced your holes closer, you could get away with less, maybe 6", but I tend towards overkill. I had to notch the bottom corner to clear a bulge in the unibody, then I drilled and tapped four holes to match the ones I drilled in the jeep body. I ground the old welds off of the hinge, drilled a couple more 3/8" holes to bolt it to the plate, then (after test fitting everything) I drilled and tapped the plate to match.  Then I shot it all black.  It took a little wiggling to get it into position, but the plate bolted in nice and solid.  Then I bolted the hinge to it:  And finally rehung the door:

__________________

DIRTY DEEDS, DONE DIRT CHEAP

Whatever doesn't kill you makes you stranger |

|

|

|

|

|

#3 |

|

Mechanical Animal

- CORE Member -

- Moderator - Join Date: Feb 2008

Location: Beechmont

Posts: 1,883

|

Overall, I'm thrilled with the results. I was hoping just to get the stupid door back on. But the new mount lifts it back up where it should have been all along, and it opens and closes better than it has in years.

I was careful to put the hinge right back where it was originally, and like I said, it does work well. If I was to do it again, though, I'd move the hinge forward (toward the front of the jeep) about a quarter inch. That way I could shim the door-side mount to exactly where I wanted it, and even adjust it over time if it started to sag again. All told, it took me about an hour and a half (not counting the time to pull off the fender), and since I picked the plate out of the scrap at work, I was only out seven 3/8" bolts. (Even buying a foot of the flatstock would only be $4 at OnlineMetals.) Hope it helps somebody! Robert

__________________

DIRTY DEEDS, DONE DIRT CHEAP

Whatever doesn't kill you makes you stranger |

|

|

|

|

|

#4 |

|

Retired

Join Date: May 2008

Location: Hamilton/Ross

Posts: 645

|

nice repair and write up. mine is a four door so it doesnt have quit the stress of a two door but on closer inspection someone has been in there rewelding at some point so if it happens again i see this as a better long term fix

__________________

One of these days Zuk 2.0 |

|

|

|

|

|

#5 |

|

Pure Bacon

Join Date: Jan 2007

Location: Trenton, Oh

Posts: 1,098

|

x2 on the good fix , I had to weld my 2 door up back in the day , I also have had to fix a ouple four doors .

|

|

|

|

|

|

#6 |

|

Your wifes pimp!

|

Yes, This was a very cool fix you have to beef up these uni bodies anywhere you can and that problem is so common. You could sell a kit for it.

__________________

if i am not currently offending you, i will be shortly. |

|

|

|

|

|

|